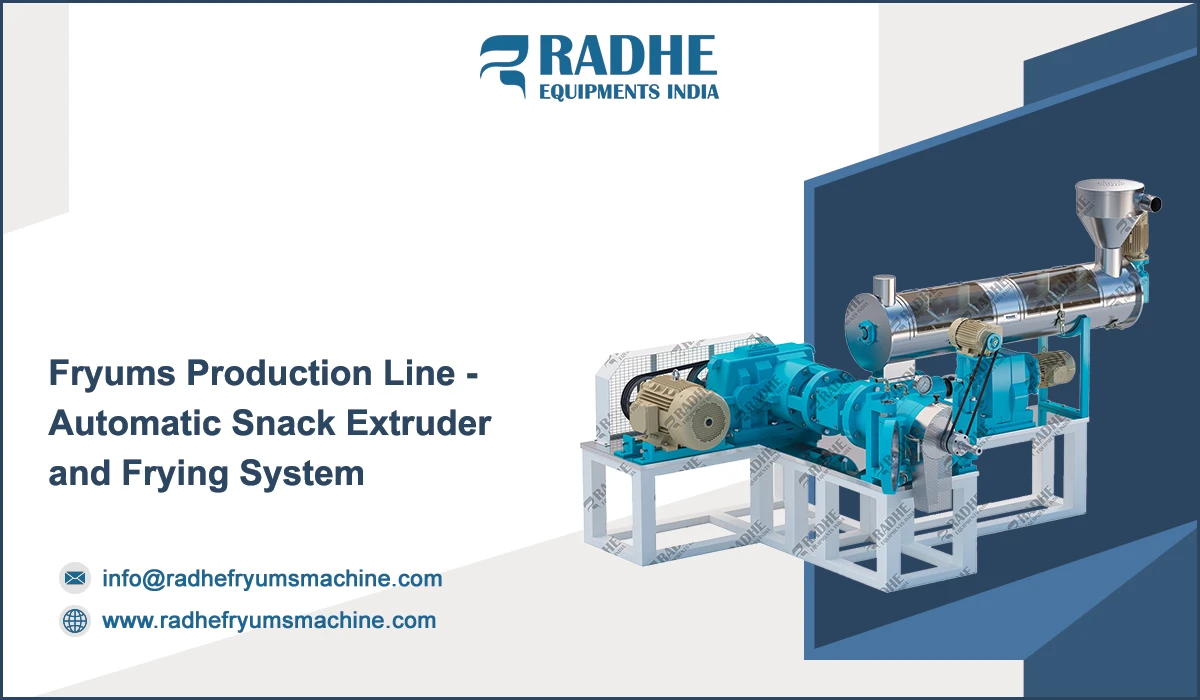

Fryums Production Line - Automatic Snack Extruder And Frying System

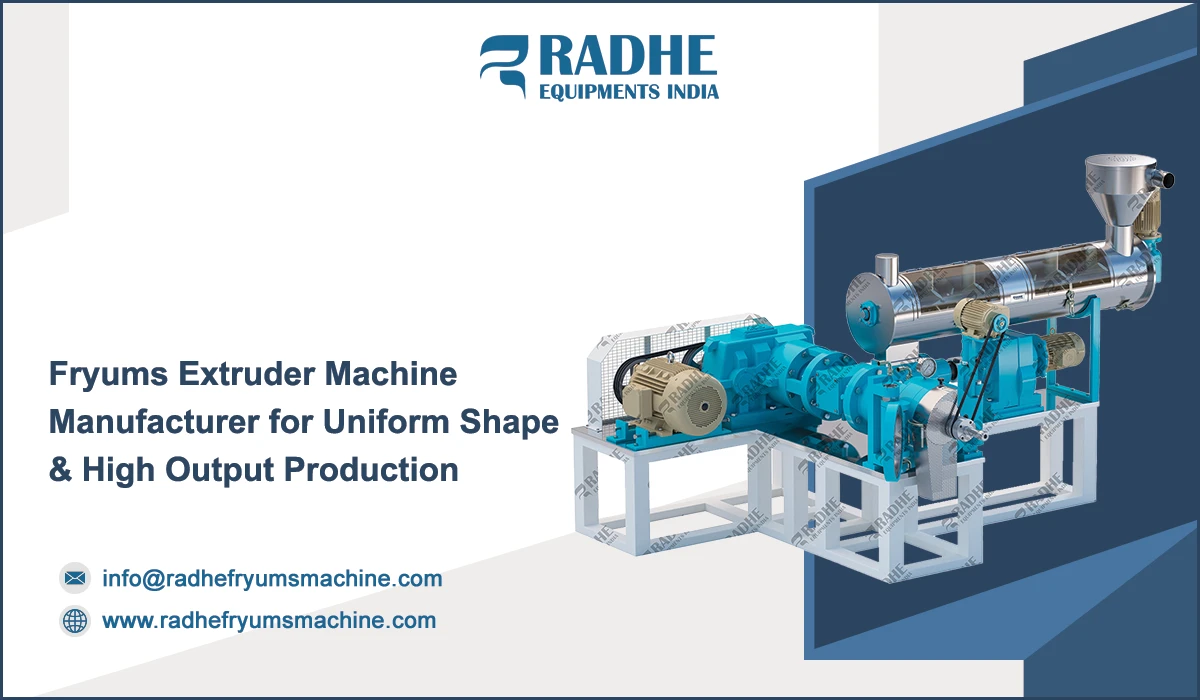

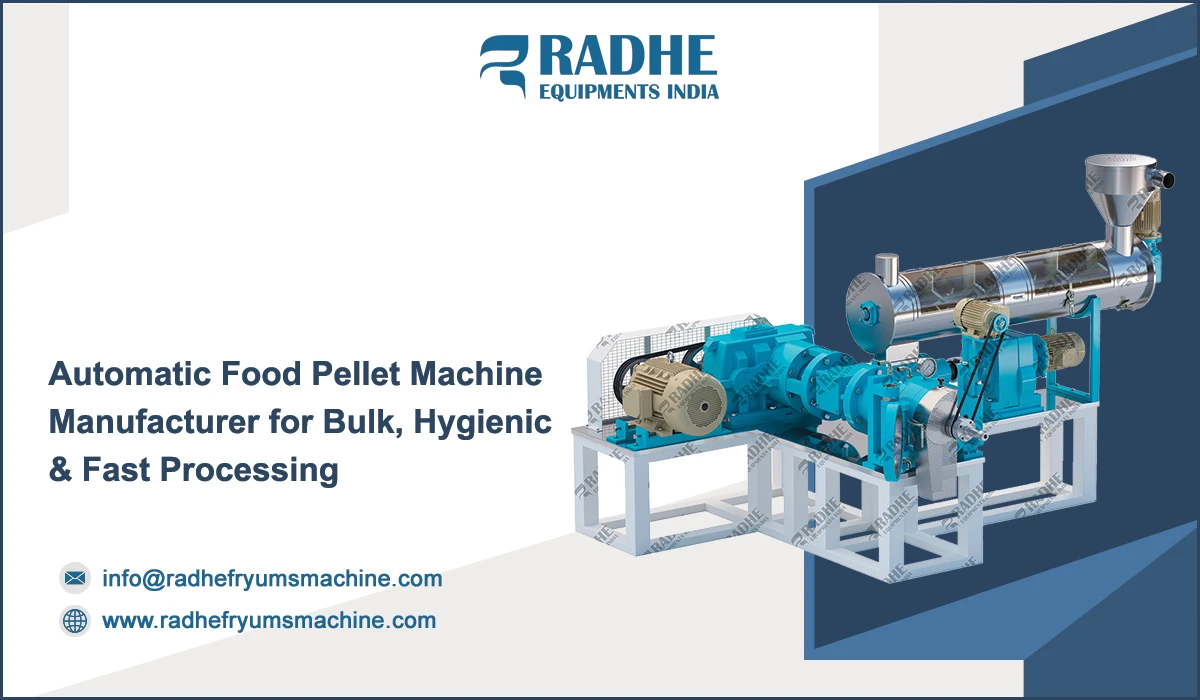

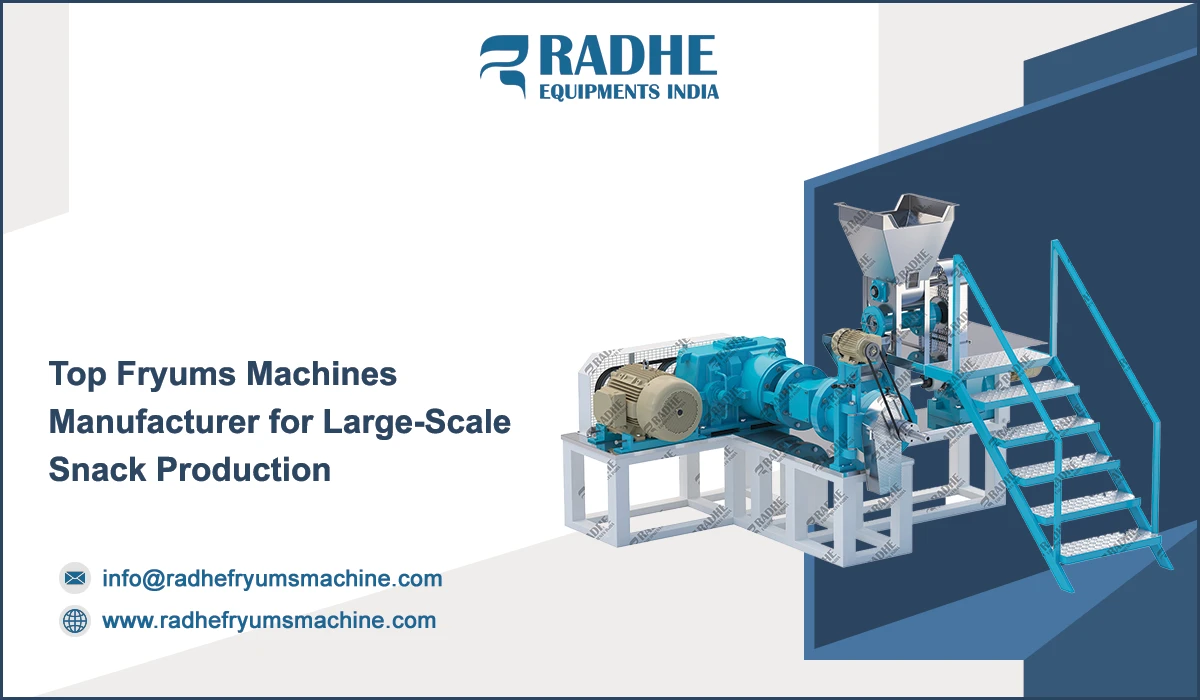

The Fryums Production Line - Automatic Snack Extruder and Frying System is a complete and fully automatic setup designed to make tasty and crispy fryums in large quantities with minimum effort. This production line is ideal for snack manufacturers who want high output and consistent quality in every batch. The machine line includes an automatic extruder, cutting system, dryer, and frying unit that work together to deliver ready-to-pack fryums.

It can process various raw materials like potato starch, corn flour, and wheat flour to make different fryum shapes such as stars, wheels, tubes, and more. The automatic control system ensures uniform temperature and perfect frying results every time. It is built with durable stainless steel parts for long life and easy cleaning. This system reduces labor, saves energy, and improves productivity. Whether you are starting a new snack business or upgrading your existing plant, this machine is the perfect solution for large-scale, hygienic, and efficient fryum production.

Fully Automatic System: Complete line from mixing to frying with minimal manual work.

Multi-Shape Output: Produces star, ring, wheel, tube, and other fun shapes.

Energy Efficient: Uses less oil and power for cost-effective production.

High Production Capacity: Suitable for large-scale snack industries.

Durable Build: Made of stainless steel for hygiene and long service life.

Uniform Frying: Consistent temperature control for even frying results.

Easy Operation & Cleaning: Simple control panel and low maintenance design.