550 Fully Automatic Line

Overview:

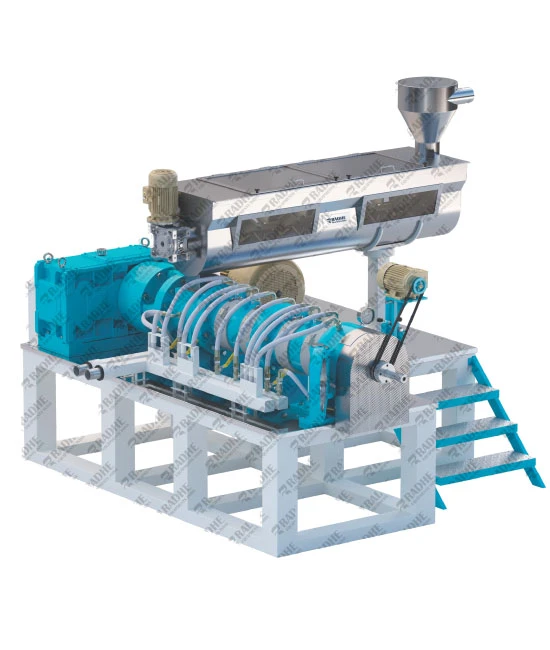

The 550 KG/HR Fully Automatic 2D Pellet Machine Line is designed for large-scale manufacturers seeking unparalleled production capacity and efficiency. With its cutting-edge automation and continuous operation features, this machine delivers massive output while reducing labor requirements to a minimum. Capable of running 24x7, this line is built for businesses looking to ramp up production, reduce operational downtime, and meet high demand with consistent, top-quality 2D pellet shapes.

Machinery Included:

· Water Mixture

· Flour Mixture

· Gelatinizing Machine

· Forming Machine

· 8 Deck Vibro Dryer

· Continuous Dryer

· 8 Deck Vibro Dryer

· Thermic Fluid Heater